neue Produkte

Finden Sie Achse Schweißmaschine, Achsenschweißroboter, Automatische Schweißmaschine auf Industry Directory, zuverlässige Hersteller / Lieferant / Fabrik aus China

\ n 1. 2015 Muldenkipper Panel Schweißmaschine Tipper Floor Automatic Welding Robot Haupteinführung \ n \ n

\ n 1. 2015 Muldenkipper Panel Schweißmaschine Tipper Floor Automatic Welding Robot Haupteinführung \ n \ n | a. Welding automatically four edges of body continuously to ensure that the torch welds one seam to change another one. | |||||

| b.Accurate positioning, precision welding. | |||||

| c.Overall control uses touch screen + PLC control, Input horizontal and vertical spaces on touch screen, and the welding gun could weld automatically body according to input values. | |||||

| d.Welding Power:TPS4000 – A milestone in the history of the welding product, it is a kind of full digital, microprocessor monitoring inverter power. In many advantages of this new equipment, especially prominent feature is that it applies to a variety of welding methods, and meets various welding tasks. TPS4000, maximum welding current is 400A, could meet the most demanding industrial requirements. | |||||

| e.This workbench is matched with dumper Panel Automatic Welding Machine, and consists of lifting conveyor device, positioning device, and fixtures. |

| Longitudinal Drive mode | Gear, rack + servo motor, planetary gear reducer | ||||

| Horizontal drive mode | Gear, rack + servo motor, planetary gear reducer | ||||

| Linear guide | Hiwin | ||||

| Vertical effective travel | 8000mm | ||||

| Horizontal effective travel | 1800mm | ||||

| travel of moving body Up and down | 180mm | ||||

| Control mode of welding gun up and down | Spot laser detection | ||||

| Appearance layout of cables | Tractor chain | ||||

| Control mode of moving body up and down | Servo motor + ball screw | ||||

| Frame | Cantilever type | ||||

| Power source | Fronuis TPS4000,Panasonic KR500 | ||||

| Main voltage | ±15% 50/60Hz 3 ×400V | ||||

| Welding current range | MIG/MAG 3—400A | ||||

| Welding current range | TIG 3—400A | ||||

| Welding current range | MMA 10—400A | ||||

| Welding cycle (40 ° C, 10 min) | 50% duty cycle, 400A | ||||

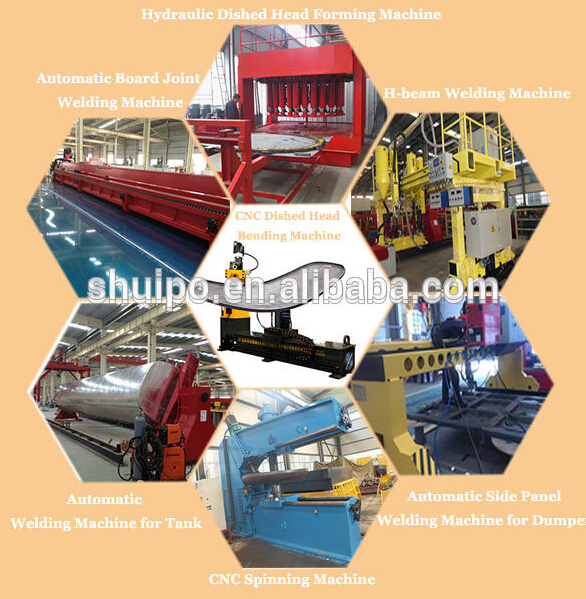

\ n 3.Mehr Produkte für Sie wählen über 2015 Muldenkipper Panel Schweißmaschine Tipper Floor Automatic Welding Robot \ n

\ n 3.Mehr Produkte für Sie wählen über 2015 Muldenkipper Panel Schweißmaschine Tipper Floor Automatic Welding Robot \ n

\ n Unternehmensinformationen \ n 1.Mehr über unsere Firma \ n

\ n Unternehmensinformationen \ n 1.Mehr über unsere Firma \ n

\ n

\ n Produktgruppe : Schweißgerät